Custom Equipment & Factory Automation Blog

The success of custom OEM equipment design and factory automation projects depend as much on planning and strategy as it does execution. The Phase 1 from Owens Design is a process for optimizing trade-offs, identifying critical dependencies, finding requirement gaps, and developing […]

The path to success for a manufacturing startup of complex, automated technology is never easy, no matter what the product. One of the earliest hurdles is obtaining the funding needed to realize your vision. While it may not sound as intimidating as […]

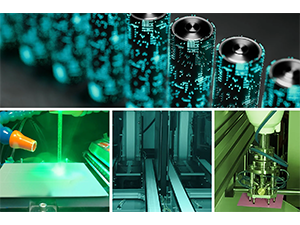

Obtaining automated, precise cutting on a critical, fragile layer at high production volumes An EV battery manufacturing startup needed to scale their production volume to meet the growing demands of their customers. A critical step of their innovative product required precise cutting […]

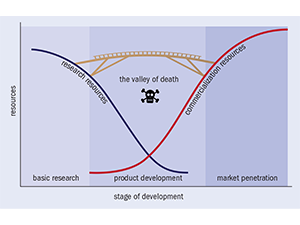

The startup journey can be a perilous race to transform your lab-scale idea into a market-ready product and includes significant hurdles. The most notorious is the so-called “Valley of Death,” from which many manufacturers never escape – but there is a way […]

Learn How to Access CHIPS Act & Other Government Funding Opportunities Are you an upstream or downstream semiconductor manufacturer looking to secure crucial funding for your projects? The CHIPS Act presents a once-in-a-generation opportunity, providing a staggering $113 billion in manufacturing incentives. […]

Meet with the Owens Design engineering team to learn how to accelerate semiconductor equipment design and development With the semiconductor market expected to reach $1,380 billion by 2029, you can’t afford delays in time to market, as you navigate supply chain uncertainty, […]

Owens Design CEO, Bob Fung will speak alongside other advanced manufacturing industry leaders at Silicon Valley Business Journal’s Future of Fremont event on June 27 at the Fremont Downtown Event Center. Bob will join the Manufacturing and Advanced Industry Panel starting at […]

Many advanced technology OEM startups and companies needing custom factory automation turn to a partner to co-develop mission critical programs. Like many outsourcing practices, this comes with its own set of challenges especially when doing so for the first time. Development managers […]

How often have you been well down the development path only to suddenly be derailed by a new requirement? How often did that requirement come from someone you didn’t even know was a stakeholder? Changing requirements, either due to scope creep or […]

Imagine that your general manager challenges you to significantly reduce the cost of your current automation tool, and gives you three months to demonstrate the cost reduction results on a first-generation prototype. Never mind going to the purchasing group: the GM has […]